Category

TAGS

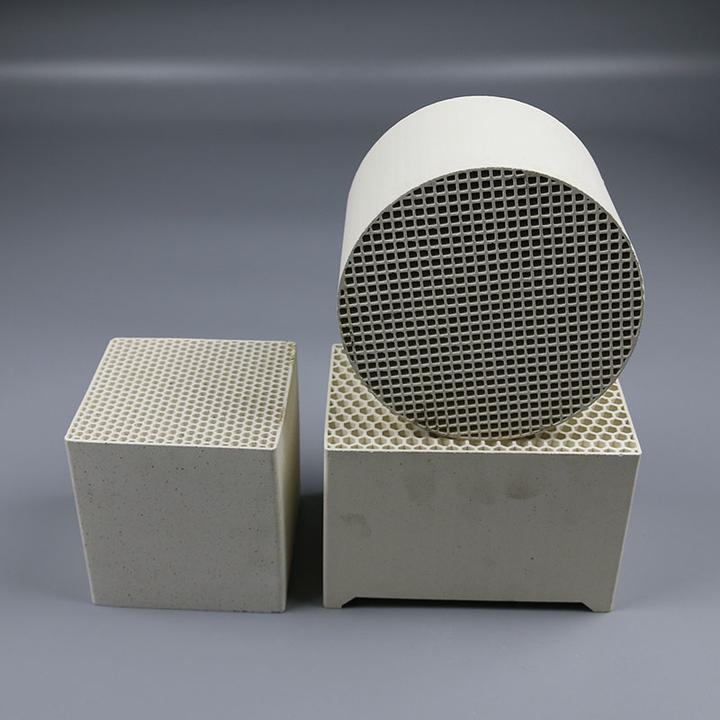

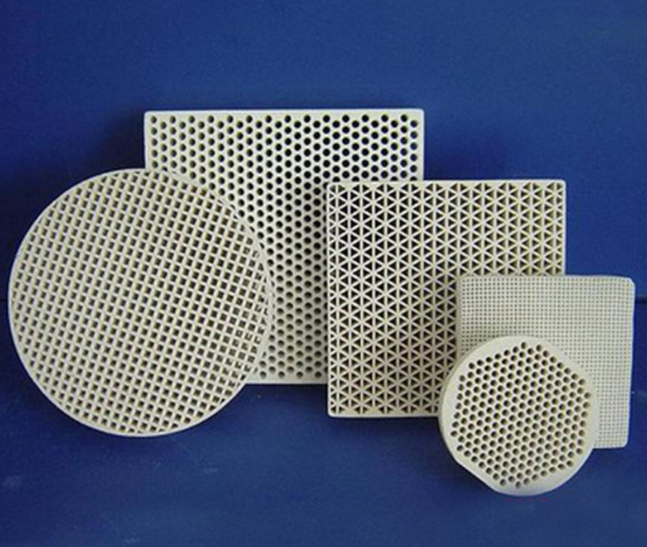

Ceramics for RTO/RCO equipment

Ceramic honeycomb

KEHANTEK supports customization, recommending and customizing high-quality and suitable product solutions based on customers' specific applied environment, appearance, and performance requirements.

Request a Quote info@kehantek.comShare us :

PRODUCTS IN DETAIL

Honeycomb ceramics are a new type of ceramic product with a honeycomb-like structure and are an environmentally friendly ceramic material. They have high strength, high temperature resistance, corrosion resistance, and wear resistance, and are widely used in chemical, electric power, metallurgy, petroleum, electronic appliances, machinery and other industries.

Honeycomb ceramics can be made of a variety of materials. The main materials include: cordierite, mullite, aluminum titanate, activated carbon, silicon carbide, activated alumina, zirconium oxide, and composite matrices such as silicon nitride and cordierite-mullite, cordierite-aluminum titanate.

Honeycomb ceramics can be divided into four categories according to their applications: heat accumulator, fillers, catalyst carriers and filter materials.

Honeycomb ceramics are used as heat accumulators with a heat capacity of more than 1000 kJ/kg. The maximum operating temperature of the product is ≥1700℃. They can save fuel and increase production in heating furnaces, roasters, soaking furnaces, cracking furnaces and other kilns.

Honeycomb ceramics as fillers have a larger specific surface area and better strength than other shaped fillers. They can make the gas-liquid distribution more uniform, reduce the bed resistance, and extend the service life.

Honeycomb ceramics have more advantages in catalysts. They use honeycomb ceramic materials as carriers, adopt unique coating materials, and are prepared with precious metals, rare earth metals and transition metals. Therefore, they have the advantages of high catalytic activity, good thermal stability, long service life, and high strength.

Honeycomb ceramics as filter materials improve the ability of the filter to adsorb and capture fine impurities. It has better filtering effects than traditional porous ceramics and allows for smoother flow of molten metal.

MORE PRODUCTS

SEND MESSAGES

Leave your details and message below. We will respond as quickly and willing to exchange ideas with you.