Category

TAGS

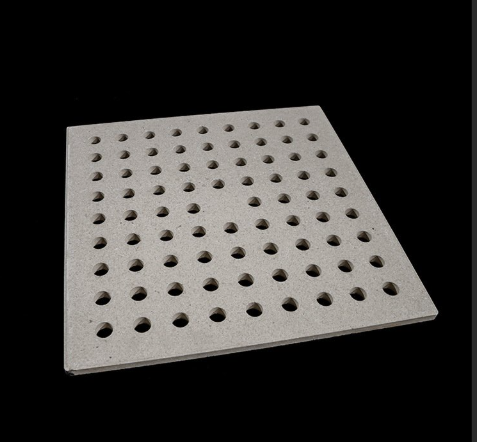

Ceramic custom products

Mullite product

KEHANTEK supports customization, recommending and customizing high-quality and suitable product solutions based on customers' specific applied environment, appearance, and performance requirements.

Request a Quote info@kehantek.comShare us :

PRODUCTS IN DETAIL

Mullite ceramics can be divided into ordinary mullite ceramics and high-purity mullite ceramics.

high-temperature protection tubes.

Ordinary mullite ceramics:

Using aluminosilicate natural minerals as the main raw materials, it is made by the reaction sintering method of mullitizing during the sintering process or by synthesizing mullite first and then forming and sintering. Due to the low purity of the raw materials and the high impurity content, there is a certain amount of glass phase in the products, resulting in poor mechanical and thermal properties, so that the excellent performance of mullite ceramics at high temperatures cannot be fully utilized. Therefore, in industry, ordinary mullite ceramics can only be used as general refractory materials in occasions where the temperature and high-temperature strength requirements are not high.

High-purity mullite ceramic:

If mullite ceramic without glass phase is prepared by reaction sintering high-purity Al2O3 powder and high-purity SiO2 powder or by synthesizing ultra-fine high-purity mullite powder, it is called high-purity mullite ceramic. High-purity mullite is a high-quality refractory raw material. It has the characteristics of uniform expansion, excellent thermal shock stability, high load softening point, small high-temperature creep value, high hardness, and good chemical corrosion resistance. As the temperature rises, the strength and toughness not only do not decay but increase significantly, which is an excellent characteristic of high-purity mullite ceramic as a high-temperature material.

Application fields of mullite ceramics:

Refractory materials

Mullite ceramics have the characteristics of high melting point, creep resistance, low expansion coefficient, excellent thermal shock resistance and corrosion resistance. Mullite refractory bricks can be used as linings for various high-temperature kilns, including melting kilns, blast furnaces, cement high-temperature calcination areas, hot iron pouring troughs and continuous casting furnaces.

High-temperature engineering materials

Mullite ceramics are also widely used in heat-resistant materials such as metal melting crucibles, high-temperature protection tubes, and thermocouple protection tubes. They are more resistant to high-temperature gas corrosion than alumina ceramics, and have good air tightness. As a high-temperature engineering material, they are particularly suitable for making high-temperature protection tubes.

Electronic packaging materials

The signal transmission time of pure mullite material is about 14% lower than that of aluminum ceramic substrate. If mullite-glass and cordierite composite materials are used, the transmission time will be further reduced.

MORE PRODUCTS

SEND MESSAGES

Leave your details and message below. We will respond as quickly and willing to exchange ideas with you.