Category

TAGS

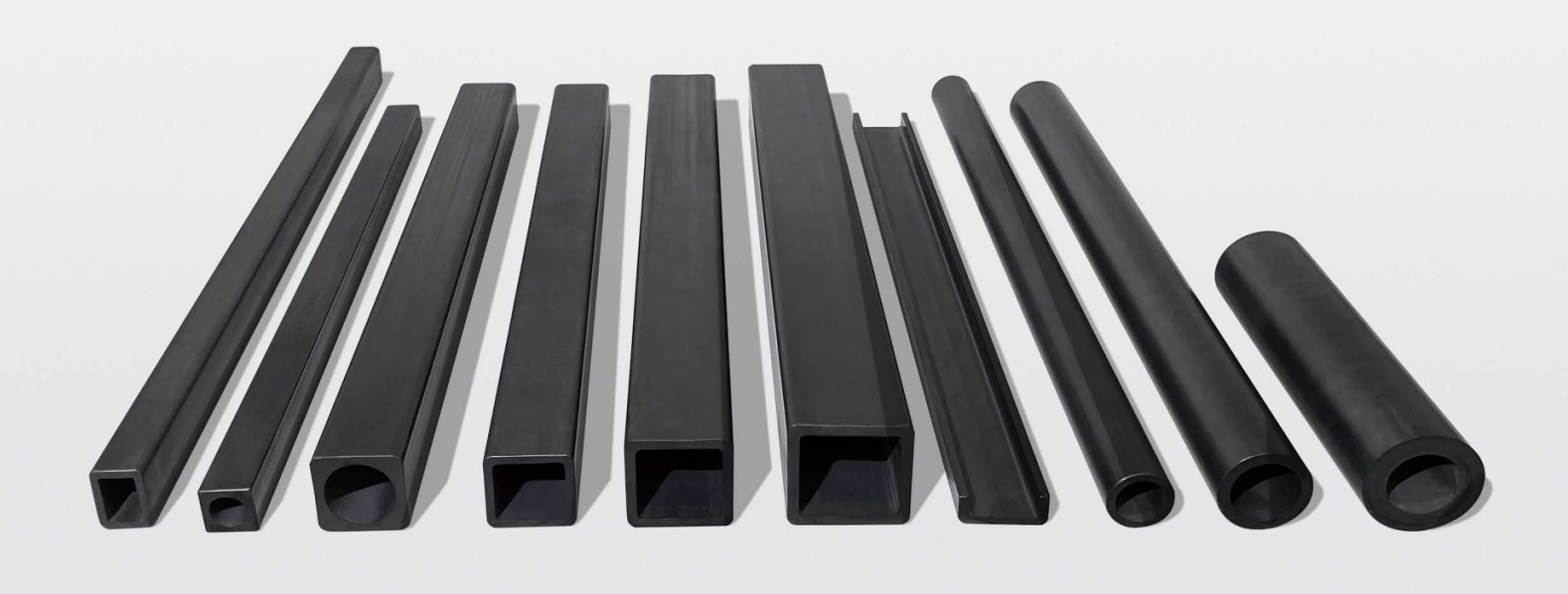

Ceramic custom products

Silicon Carbide product

KEHANTEK supports customization, recommending and customizing high-quality and suitable product solutions based on customers' specific applied environment, appearance, and performance requirements.

Request a Quote info@kehantek.comShare us :

PRODUCTS IN DETAIL

Silicon carbide ceramic materials have good wear resistance, thermal conductivity, oxidation resistance and excellent high-temperature mechanical properties, and are widely used in energy and environmental protection, chemical machinery, semiconductors, national defense and military industries.

Classify:

Reaction sintering of silicon carbide

The advantages of reactive sintering of silicon carbide are low sintering temperature, low production cost, high degree of material densification, especially in the process of reaction sintering, there is almost no volume shrinkage, especially suitable for the preparation of large-size complex shape structural parts. High-temperature kiln furniture materials, radiant tubes, heat exchangers, desulfurization nozzles, etc. are typical applications of reactive sintered silicon carbide ceramics.

Atmospheric pressure sintered silicon carbide

The atmospheric pressure sintering technology of SiC has become mature, and its advantages are that the production cost is low, and there is no restriction on the shape and size of the product, especially the solid-phase sintered SiC ceramics have high density, uniform microstructure, and excellent comprehensive material properties. Wear-resistant and corrosion-resistant sealing rings and sliding bearings, which are widely used in industry, are mainly atmospheric pressure sintered silicon carbide.

Recrystallized silicon carbide

Recrystallized silicon carbide does not contain any metallic phase and glass liquid phase, and has high porosity (10% ~ 20%), resulting in excellent high temperature resistance and thermal shock resistance. This, combined with its good thermal conductivity at high temperatures, makes it an ideal candidate for high-temperature kiln furniture, heat exchangers or combustion nozzles.

MORE PRODUCTS

SEND MESSAGES

Leave your details and message below. We will respond as quickly and willing to exchange ideas with you.